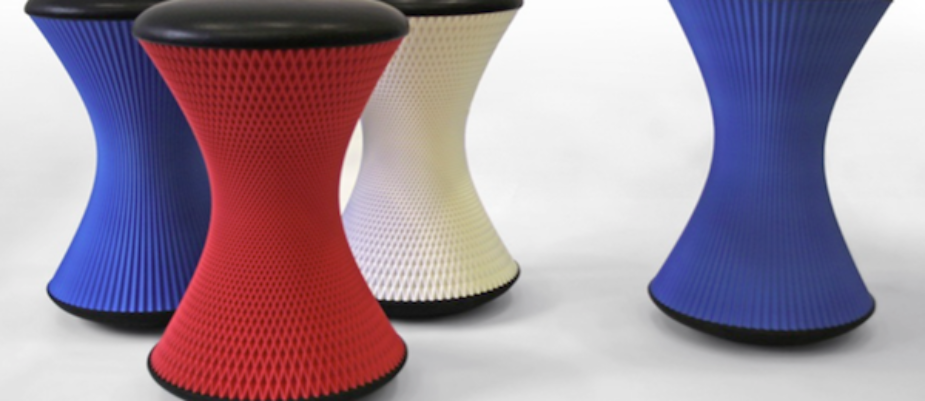

The collaboration of Wilkhahn with the designer Thorsten Franck has produced PrintStool One, a stool collection whose shapes are ideal for 3D production with its sparing use of materials. The Orgatec showcase will feature prototypes of the current stage of development to try out in diverse colours and shapes (Hall 6.1 B88).

3D printing is considered a key technology in Industry 4.0; this techniques allow the roles of producer and consumer to merge: customers become prosumers. Once they send their printing jobs, they control production and can become co-designers who define structures, shapes, colours and even sizes.

It’s the innovative technology that makes the progressive design and aesthetic of the PrintStool One possible in the first place. The sophisticated, three-dimensional structures of the stool’s body stand out for efficient use of material. The stool is very strong due to the clever way the seat and base are connected and it can take people weighing up to 100 kg.

The renewable and fully biodegradable printing material also has huge potential. The results are simply sent as data sets to 3D printers that produce the stools within just a few hours.